All Ftech products are hand-made in our Italian factory utilising the extensive expertise and experience of our seamstresses.

With the support of ASG Bike Science, Ftech’s ongoing commitment to research and development and its mission to customise each product to meet and satisfy the most precise needs and requests of our clients: cyclists of all levels, events, clubs and corporations. We are bound to our customers through a shared passion for cycling.

Our clients become part of our extended family of friends and partners and we love collaborating when we work – there is nothing ‘usual’ about our business and there is nothing that’s too much trouble. The typical project will start with a client brief, sharing of graphic ideas, project scope, order size discussion and delivery time frame requirements.

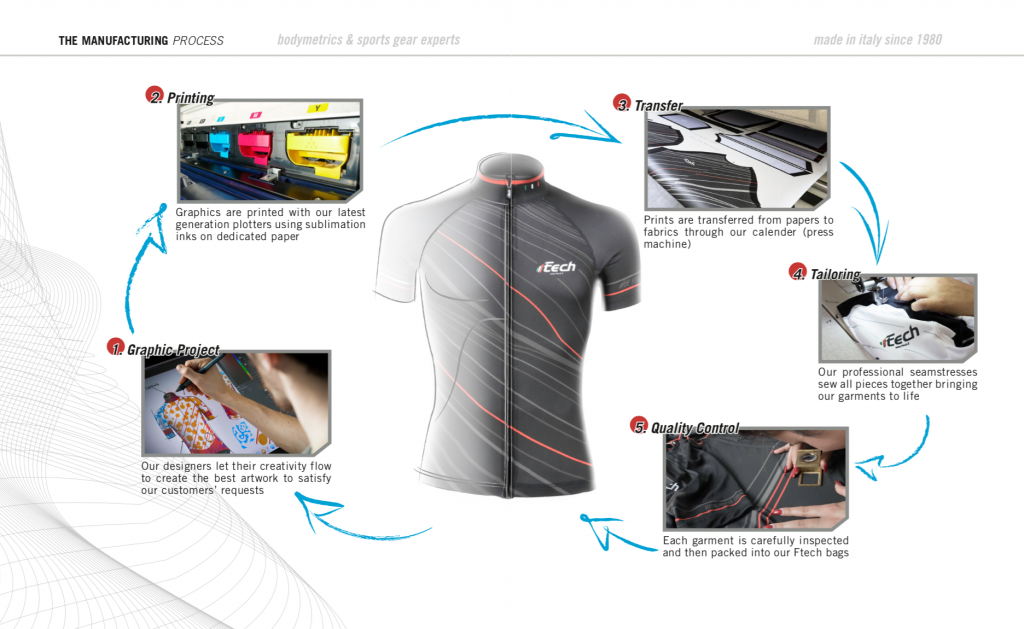

Once graphic designs are approved, production can start. Materials are laser cut, and thermoprinting applied with absolute precision. Stitching follows which is an equally delicate and complicated process. Many years of sewing experience is an absolute requirement to achieve the desired results and to meet our quality control standards.

Our clients are invited to visit our facility in Mussolente (Italy) at any time – It would be an honour to give you a personal tour and our staff is ready to welcome you with ASG hospitality. Alternatively, we can work online or through our network of partners that are ready to engage with you wherever you might find yourself in the world.